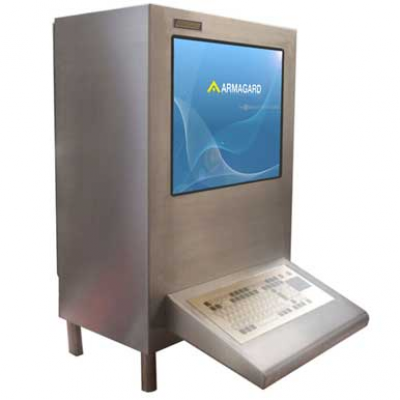

An Armagard intrinsically safe computer enclosure ensures you comply with the ATEX directive.

What is the ATEX directive?

ATEX is a European directive that ensures electronic or electrical equipment is certified for use in hazardous environments.

It was first introduced on March 1, 1996 but only became a legal requirement to all European Union member states on July 1, 2003. It was last updated in 2016.

What does the ATEX directive apply to?

ATEX applies to facilities in which there’s a risk of explosions caused by combustible materials. Examples include:

- Power stations

- Gas stations

- Foundries

- Chemical plants

If powders, dust, paint fumes, or any other combustible substance can be found in your facility, you need to be ATEX compliant. So, the directive defines explosive environments as those with high concentrations of dust, gas, mist, or vapour in the air that can cause fire or explosion.

Companies that design, manufacture, and sell ATEX enclosures also need to adhere to the ATEX directive, including Armagard.

An Armagard airtight, intrinsically safe computer enclosure.

ATEX area classifications

Employers are required to identify areas in the workplace where explosions can occur. These are divided into zones, which are then classified depending on how long the threat is present, the likelihood of an explosion occurring, and their size.

The ATEX directive classifies zones in the following ways:

Dust, vapours, and mist zone classifications

Zone 0 – A place where an explosive atmosphere consisting of dangerous substances in the form of gas, vapour, or mists, mixed with air, is present continuously, for long periods or frequently.

Zone 1 – A place where an explosive atmosphere consisting of dangerous substances in the form of gas, vapour, or mist, mixed with air, is likely to occur in normal operation on an occasional basis.

Zone 2 – A place where an explosive atmosphere consisting of dangerous substances in the form of gas, vapour, or mist, mixed with air, which is not likely to occur but, if it does, will only persist for a short amount of time.

Dust only

Zone 20 – A place where an explosive atmosphere, in the form of a cloud of combustible dust, is present continuously, for long periods or frequently.

Zone 21 – A place where an explosive atmosphere, in the form of a cloud of combustible dust, occurs in the air during normal operation on an occasional basis.

Zone 22 – A place where an explosive atmosphere, in the form of a cloud of combustible dust, is present in the air but not likely to occur in normal operation. If it does, it will only be for a short period of time.

ATEX equipment classifications

When employers have classified a zone, they can assign equipment to meet the requirements. The ATEX equipment requirements are:

- Category 1 equipment for zone 0 or 20 areas

- Category 2 equipment for zone 1 or 21 areas

- Category 3 equipment for zone 2 or 22 areas

Category 1 equipment can also be deployed in zone 1 and 21 areas, while category 1 and 2 equipment is suitable for zones 2 and 22.

An Armagard ATEX 2 enclosure in use.

ATEX enclosures

ATEX enclosures are a much more cost-effective alternative to air purged computer systems, making them an affordable way of complying with the ATEX directive.

ATEX enclosures are also more flexible. They can be used with your current equipment, which can then be easily replaced without having to change enclosure.

Armagard’s intrinsically safe ATEXenclosure is a good example of a flexible, cost-effective unit that ensures you, your employees, and your business remain safe.

The Armagard intrinsically safe enclosure is ATEX 2 and 22 compliant, waterproof, and dustproof to IP65 standards. It’s also manufactured using food grade (316) stainless steel, making it corrosion resistant and easy to wash.

But why invest in Armagard’s ATEX enclosure?

- If your business is required to be ATEX compliant but isn’t, it could face a fine of up to £5,000. A three-month prison sentence could also be handed out.

- Even worse, an explosion could destroy your entire business, a potential risk to life.

To ensure you don’t face such problems, contact Armagard now.