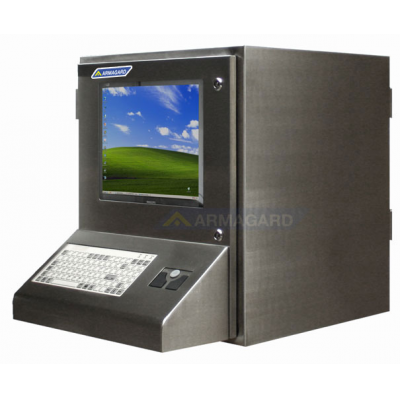

An Armagard stainless steel PC enclosure utilizes 316 grade stainless steel.

Armagard is frequently asked: ‘what is the difference between 304 grade stainless steel and 316 grade stainless steel?’. The question is often followed by: ‘which is best?’

Armagard are manufacturers of stainless steel PC enclosures, printer enclosures, and digital signage enclosures, so are familiar with the use of stainless steel.

Armagard’s stainless steel PC enclosure

Armagard prefers to manufacture PC enclosures and printer enclosures using 316 grade stainless steel. However, that doesn’t mean that 304 grade stainless steel is useless. Each grade has its own uses.

What’s the difference between 304 and 316 grade stainless steel?

There are no visual differences between 304 and 316 grade stainless steel. Both are polished, grained, and finished in exactly the same way. The only way to test which is which is by requesting an MTR (material test report).

The differences are slight and can only be found in the materials. They are as follows:

- 304 – contains 18% chromium and 8% nickel

- 316 – contains 16% chromium, 10% nickel, and 2% molybdenum

An Armagard stainless steel PC enclosure protects your PC from damage.

What do these differences mean?

With the addition of molybdenum in 316 grade stainless steel, the resistance to corrosion is enhanced, especially against chlorides. This means it is protected from sea water and de-icing salts.

Why choose 304 grade stainless steel?

304 grade stainless steel is the most versatile and widely used. It is capable of meeting a wide range of requirements. This makes it ideal for applications such as wheel covers, storage tanks, and kitchen equipment.

304 grade stainless steel provides good resistance against light to moderate acid attack, but not as much protection as 316 stainless steel.

Why choose 316 grade stainless steel?

Compared with 304 grade stainless steel, 316 has a higher resistance to heat and corrosion. This is due to the presence of molybdenum.

316 grade stainless steel is also more resistant to chemical solutions, including sulphuric acid, bromides, and iodides. This makes it ideal for pharmaceutical facilities and medical environments.

Some pharmaceutical facilities require grade 316 stainless steel by law to prevent metallic contamination.

An Armagard stainless steel PC enclosure can be fitted with or without a keyboard.

So, which is best?

This is subjective as both steel types have their uses.

For example, people within the security industry prefer type 304 steel, as they feel the corrosion resistance in 316 grade steel isn’t superior enough.

They also believe that 304 type steel can withstand greater physical impact, making it better for security applications.

However, industrial workers argue that 316 type steel offers greater protection against physical impact and corrosion.

It is down to the purchaser of the stainless steel to decide which is best for them and the application they need it for.

The Armagard perspective

A large proportion of Armagard’s SENC stainless steel PC enclosure and printer enclosure ranges are manufactured for environments in which resistance to corrosion is important.

Armagard products are supplied to food manufacturers, pharmaceutical companies, and medical institutions all around the world. Therefore, corrosive metals need to be considered.

Because of this, Armagard prefers using 316 grade stainless steel. It provides a high resistance to corrosion and staining. It also has antibacterial properties and is low maintenance. Because of this, it is beneficial for Armagard’s customers.