Choose the ideal industrial valve with this range of ball valve types

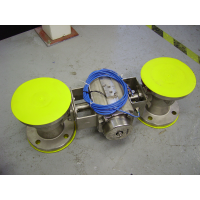

Ball valves [Ball valves]

Omega Valves has numerous ball valve types available to meet your requirements.

Ball valves are used for isolating or controlling the flow of fluids. The ball valve can be operated either manually by hand (locally) or automatically by an actuator (remotely).

Ball valves have a low fluid resistance and high CV values, which is dependent on the size of the bore. The ball valves can be easily cleaned and maintained. The valves are easy to fit, repair and are designed in standardised dimensions based on size and pressure ratings.

The ball rotates to 90⁰ or for a quarter turn to open or close the valve. Other specific applications are possible by opening the valve at fixed points of 10⁰, 20⁰, 40⁰ and 45⁰. Most ball valve types are bi-directional and can be rotated in either direction.

Ball valves are suitable for the following applications

- Most ball valve types are suitable for fluids.

- Hard valve balls and seat materials are available for abrasive materials.

- Special polytetrafluoroethylene (PTFE) coated ball valves are available for applications involving acids and aggressive chemicals.

Note: Special materials are available on request for the application of ball valves in extreme temperatures.

Ball valves are suitable for the following locations

- Houses

- Offices

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment plants

- Gas works

All ball valve types supplied by Omega Valves comply with the following standards and accreditation's.

Standards

- Top flange: ISO 5211

- Flanges: ANSI B16.5

- Face to face (FTF): ANSI B16.10

- Testing: API 598, API 6D, BS6755-1

- Design: API 6D, B16.34

- Materials: NACE MR0175

Official approvals

- Certificate fire safe

- TA-LUFT

- ATEX 94-9EC

- API 6D.

- PED 97/23/CE.

- SIL 3 CAPABLE

- EN 161/EN 264

Omega Valves has the following ball valve types.

- Full range of floating ball valves available to BS 5351 standard. The size ranges from 0.5 inches to 12 inches.

- Full range of trunnion mounted ball valves with API 6D and BS 5351 accreditations. The size ranges from 2 inches to 56 inches.

- Full and reduced bore.

- ANSI class 2500 and DIN standard PN420.

- Cast iron, carbon steel, low temperature carbon steel, and stainless-steel material are available.

- Metal alloy and duplex steel are available on request.

- Supplementary testing of RT, MT, DP, PMI Ect and special metallurgy is available on request.

- Fire resistant to API 607 / BS 6755 Pt. 2 and ISO 10497 standards.

For specialised ball valves, get in touch with us now. We will be pleased to offer you a complete solution to fulfil your requirements.