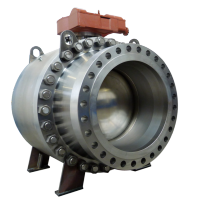

Increase manufacturing efficiency with a ball valve with actuator

ball valve with actuator [ball valve with actuator]

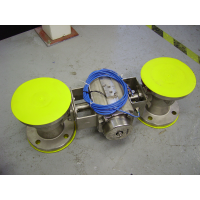

The ball valve with actuator is an efficient tool for automating any industrial process. The wide range of options, materials and configurations enable the ball valve to be controlled by a button and monitored live. The two common valve actuators are pneumatic and electric actuators. Actuators mounted on the ball valves are known as ‘rotary actuators’.

After the ball valve with actuator is assembled (with either the pneumatic or electric actuator), air or electricity is supplied to the actuator. The ball rotates to 90⁰ or for a quarter turn to open or close the valve. Other specific applications are possible by opening the valve at fixed points of 10⁰, 20⁰, 40⁰ and 45⁰.

The ball valve with actuator eliminates the need for an operator to stay near the valve and operate the valve manually. The operator can now control the movement of the valve remotely, from the control room.

The following accessories enhance the use of the ball valve with actuators

- The switch box informs the operator when the valve is open or closed.

- The electro-pneumatic positioner controls the valve using a 4-20mA signal.

- The Namur solenoid valve controls the air supply with an electrical signal.

- The enclosure helps fulfil the ATEX requirements

- Quick exhaust valve

- Air filter regulator

- Throttle plate

- Needle valve

Main factors to consider when selecting a ball valve with actuator

- The substance

- Available instrument air

- The valve line pressure

- Temperature

- How often the valve will be operated

- Valve torque

- Environment

- Moisture levels

Ball valves are suitable for the following applications

- Most ball valve are suitable for fluids.

- Hard valve balls and seat materials are available for abrasive materials.

- Special polytetrafluoroethylene (PTFE) coated ball valves are available for applications involving acids and aggressive chemicals.

Note: Special materials are available on request for the application of ball valves with actuator in extreme temperatures.

The ball valve with actuator is used in the following locations

- Houses

- Offices

- Hospitals

- Manufacturing factories

- Oil refineries and oil rigs

- Power stations

- Water treatment factories

- Gas works

- ATEX areas

- Offshore locations

ISO Mount is an international standard guide that simplifies the process of assembling the ball valve with the actuator, accurately.

The ball valves comply with the following standards and accreditation's

Standards

- Top flange: ISO 5211

- Flanges: ANSI B16.5

- Face to face (FTF): ANSI B16.10

- Testing: API 598, API 6D, BS6755-1

- Design: API 6D, B16.34

- Materials: NACE MR0175

Official approvals

- Certificate fire safe

- TA-LUFT

- ATEX 94-9EC

- API 6D.

- PED 97/23/CE.

- SIL 3 CAPABLE

- EN 161/EN 264

The pneumatic actuator complies with the following standards and regulations

- Quality System Management UNI EN ISO-9001:2008

- Authorization to Export Russian Federation, Belarus, Kazakhstan TU-CRE

- Declaration of E.S.H.R. Compliance Machinery Directive 2006/42/CE

- SIL-3 Safety Integrity Level IEC EN 61508/61511

- IP67 Protection Code Declaration EN 60529/A1:1999

- Declaration of Conformity for Using in Explosive Environments (aluminium) ATEX 2014/34/UE

- Declaration of Conformity for Using in Explosive Environments (stainless steel) ATEX 2014/34/UE

- Declaration of Conformity Design, Manufacture and Testing EN 15714-3:2009

The electric actuator complies with the following standards and regulations

- SO 9001, ISO 14001, OHSAS 18001

- ATEX, NEMA, IEEE, RCC-E, SIL

- ABS, CSA, BUREAU VERITAS, GERMANISCHER LLOYDS, GOST, INERIS, TÜV

Types of ball valve with actuator

Ball valves

- 1-piece Reduced Bore Floating Ball Valve

- 2-piece Full Bore Floating Ball Valve

- 3-Piece Full Bore Floating Ball Valve

- Wafer Pattern Ball Valve

- 2-piece Full Bore Trunnion Mounted Ball Valve

- 3-Piece Full Bore Trunnion Mounted Ball Valve

Actuator

- Electric actuator

- Pneumatic actuator

- Rack and Pinion actuator

- Scotch Yoke actuator

- Stainless steel actuator

- ATEX actuator

- SIL 3 actuator

- PTFE coated actuator

- European manufacture actuator

- E.U manufacture actuator

- TU-CRE actuator

For more information, get in touch with us now. We will be pleased to offer you a complete solution.