Manx Engineers was established in 1945 as a family-owned precision engineering company. Since a management buy-out in 2009, the company has operated from a fully refurbished 850 m2 facility in Ramsey, on the Isle of Man. Here, it continues to build on its enviable reputation for excellent service that ensures its customers are provided with the lowest cost engineering solutions for their subcontract machining and assembly requirements.

An enthusiastic team of 22 highly skilled staff use the latest CNC machine tools run on a double-day shift support customers in a variety of precision manufacturing industries, including aerospace, medical, subsea, fluid power, dental, low volume automotive, telecommunications and piezo-technic.

Company director, Bob Ringham, recalls: “Our previous facility was an old millbuilding that was only around a third of the size of the new facility, and if we wanted a new machine tool we would have to remove something. The largest machine we could install was limited by the size of the doorway at around 7ft tall. We now have a roller shutter door for full access, which makes material handling so much moreefficient.”

The new directors remain focused on the smaller high precision milled and mill- turned components that the company has become acknowledged for supplying, ascustomers know they can rely on the business’s core competences for these parts.To support this, since the buy-out the directors have invested in three new machine tools with a new Citizen A32, a Mazak Hyper Quadrex twin-spindle twin-turret machine and a Mazak Integrex mill-turn purchased and installed.

Bob Ringham states: “We tend to invest in Citizen or Mazak because they are both reliable, high quality machine tools and our staff are familiar with them so we can move people around for holiday cover and so on. Here on the Isle of Man it is crucial that you get good backup and both these suppliers offer great service and support.”

The Citizen A32-VII sliding head lathe offers 32mm diameter machining with a rapid feed rate of 45m/min, it achieves 30 per cent higher productivity than previous machines. Capable of heavy cuts the machine is equipped with 5 axes, 6 turning tools, 4 rotary tools for cross-machining, 9 tools for back-end machining and 5 tools for front-end machining giving a total of 23 tools for flexibility. Maximum cutting length is 320mm in one chucking.

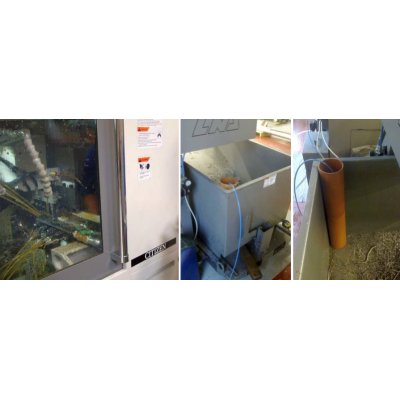

Wogaard’s newly developed neat oil Coolant Saver is fitted to the Citizen A32 that, like many sliding head lathes, uses an expensive low viscosity oil to cool thecomponent and the cutting tools during machining. Installed by the company’smaintenance staff the unit has been operating for a few months.

Primarily designed and successfully applied to the reclaiming of water miscible (soluble oil) coolant from machine tools with swarf conveyors, the Coolant Saver has seen phenomenal growth during the past 18 months. Being easy to fit and simple to use has made it popular with precision engineering businesses in across the globe. However, following many requests for the recovery of neat oil from customers using sliding heads machines, Wogaard has developed a Coolant Saver specifically for this application.

“It is too early to calculate the exact savings, but it is certainly paying for itself,” says Bob Ringham. “A barrel of neat coolant oil is an expensive necessity; if we can recover as much as possible from the swarf it makes good business sense and haspositive implications for the environment as well.”

While the parts conveyor on Citizen A32 takes the machined components away from the working envelope, these tend to be smooth and are easily drained, so the oil returns to the machine’s 220 litre sump without too much loss. However, the swarf conveyor drags the neat oil out with the chips and it is here that the Coolant Saver makes the most significant impact.

Bob Ringham explains: “As a subcontract engineering shop we machine to customers’ specifications and the materials cut range from the easy machining brassand copper through to exotics such as Inconel and titanium. Swarf is always segregated, making the extraction of the neat oil coolant even more critical as the number of swarf bins with, say, half a litre of waste coolant would soon become overwhelming".

“Added up over a week it is a significant amount of coolant and all the staff havecommented on the reduction in the number of sump top-ups required. We would add oil to the machine around three times per week, and now we have reduced this to once per week. So, the handling of the oil is reduced along with the chances ofspilling it in transit or while trying to pour it into the machine’s tank. All of whichimproves our housekeeping.”

Manx Engineers has purchased two new swarf skips that were specified and supplied with a protective sleeve in the corner to house the Coolant Saver. Bob Ringham points out that the Wogaard certainly has no problem pulling the neat oil from the skip, with the operator simply turning the unit on or off as required.

He concludes: “We are looking to expand the use of the Coolant Saver to the other twoCitizen sliding head lathes, as we can see the immediate benefit of the investment and the installation is very straightforward.”