With a passion for manufacturing an array of components and sub-assemblies using the very latest CNC technology, Roscomac has a broad range of machining competencies, with a focused approach to customer service and quality that allows the business to successfully maintain its commercial relationships within a variety of industry sectors, including aerospace, medical science and instrumentation, oil & gas, and general precision engineering.

Accredited to ISO 9001, component manufacture and supply is always totally aligned to customer specifications, processes and expectations, as either stand- alone parts or sub-assemblies, with design and product development critical elements of the Roscomac contribution.

Operating from an impressive manufacturing facility in Worthing, West Sussex, with technical customer support in Brno in the Czech Republic, the company employs almost 100 highly skilled and knowledgeable staff running around-the-clock.

A continual investment programme means machine tool technology is regularly updated, with an older rail-type FMS currently being replaced by a cell of high-speed pallet fed 5-axis machining centres.

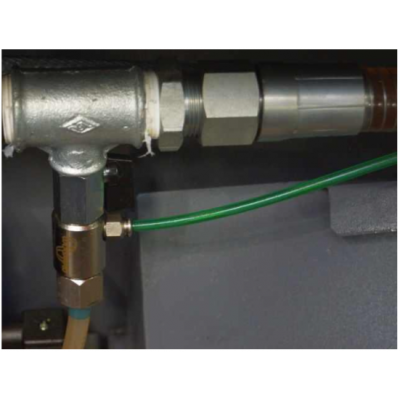

An array of Citizen Swiss-type sliding head lathes provide the majority of the turning and mill-turning capability for Roscomac, with 13 of them now fitted with theWogaard Oil Saver. As Production Manager, Sean Keet, recalls: “We recentlypurchased a number of new Citizen lathes and were made aware of the capabilities of the Wogaard Oil Saver. I contacted Wogaard’s Managing Director, Jason Hutt,and after a visit onsite he helped us install the first unit; completely free of charge for us to thoroughly evaluate it."

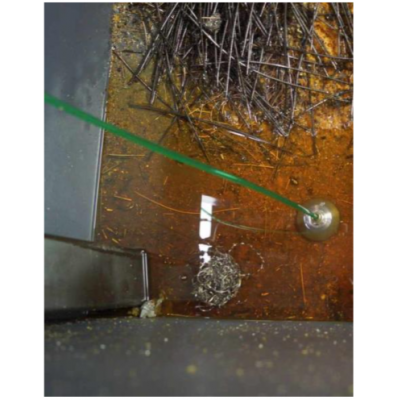

“It was a real eye-opener seeing the unit operate on that first machine, taking the neat oil back to the machine’s sump. As anyone running sliding head lathes knows,oil dragged out by the swarf is a problem, and previously we would try to allow our swarf bins to stand to let as much of the oil drain off. But in a busy production environment working around-the-clock that time is never really available.”

The range of materials machined by Roscomac reflects the spectrum of industries the business supports. For high volume applications Brass, Steels and difficult to cut materials, swarf tends to form a ‘bird nest’ around the cutting tool requiring the machine to be stopped and the tangle of cut material to be broken up and removed. Citizen has addressed this with its new LFV (Low Frequency Vibration) technology that effectively breaks up the stringy swarf using oscillation of the axes and cutting tool.

“Our new LFV equipped lathes can produce significantly more components per shift because there is no longer a need to interrupt the production run,” explains Sean Keet. “Of course, that also dramatically increased the amount of low viscosity neatoil dragged out into the swarf bins.”

“Smaller chips allow the neat oil to drain better, and we had about 7 litres a day accumulating in the bin at anything up to £5 per litre. The Oil Saver quickly pulls this back into the sump of the machine, and that alone would pretty much pay for every Wogaard unit we have in the factory. And, it is not like we spend a lot of time maintaining them, it’s a fit and forget, just put it in the swarf bin every day and check that that’s sucking up and your reclaiming your money.”

Another positive factor noted by Roscomac is the reduction in sump top-ups with neat oil for the lathes. Before the Wogaard units were fitted each lathe required replenishing up to three times each week, often with large volumes of neat oil. SeanKeet says: “Now we only have to refill the sumps once a week and as the Oil Saverreclaims the coolant back from the swarf bin in to the same sump there is no chance of cross-contamination. This amounts to a significant amount of time saved acrossall the sliding head lathes.”

He continues: “Another winner for us is the machine doesn’t stop; it doesn’t come upwith that alarm saying it has run out of oil in the middle of the shift when there is no one else about. If you are looking to continuously run, if you want any lights out running it is not going to stop. If our staff are off getting oil to fill up the machine they are not adding any value, so we have the Wogaard Oil Saver silently helping keepus running.”

Sean Keet concludes: “One of the best things you can say about the Oil Save is you don’t have to manage it once you have made sure it is up and running as we have. I don’t know how many litres we have seen reclaimed, but it makes a positive impacton the environment and that is certainly part of Roscomac’s core family values.”