Reduce waste with a machine coolant recycling system

Machine coolant recycling system [Coolant saver]

The machine coolant recycling system saves time and money and reduces waste in machining industries.

Wogaard’s coolant vacuum equipment returns waste coolant to your CNC/cutting machines. Reuse up to 50% of your coolant and help the environment.

Benefit from a one-year warranty and outstanding technical support.

Contact Wogaard to find out more.

How does the machine coolant recycling system work?

Place the stainless-steel vacuum head in the bottom of the machine’s swarf/waste bin. The vacuum sucks up coolant from the bin and returns it to the machine.

The kit is easy to install, simple to use and almost maintenance free, so it’s suitable for any business. Multiple fitting kits are available, so the kit works on a range of cutting/CNC machines.

The vacuum receives power from the machine’s coolant pump, so no external power source is required.

Benefits of the Wogaard coolant saver

|

Save money |

Reduce disposal costs by up to 90% and reuse up to 50% of your coolant. |

| Make money | Clean swarf has a higher resale value. |

| Save time | Reduce the time your employees spend emptying coolant from waste bins. |

| Improve your workplace | You experience fewer coolant leaks from waste bins. |

| Help the environment | Reduce waste, recycle coolant and use the coolant saver kit without an external power supply. |

Contact Wogaard for more information.

The machine coolant recycling system includes:

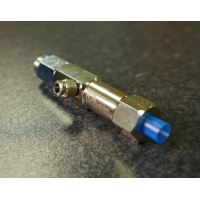

- Coolant saver unit

- Vacuum head

- Polyurethane hose: six-millimetre diameter and three-metres long (can be extended to 10 metres)

- 1.5-metre, 12-millimetre hose outlet

- T-fitting and straight-fitting kits

- Instruction manual

The CNC coolant recycling system can be installed in 30 to 45 minutes. Wogaard also provides an installation service for large machine shops.

About Wogaard Ltd

Wogaard’s aim is to reduce costs and waste in manufacturing industries. Since designing the machine coolant recycling system, Wogaard has produced an oil saver that collects waste oil and returns it to cutting machines.

Thousands of Wogaard products are in use all over the world, and the company has a wide base of happy customers.

You benefit from industry-leading expertise, a one-year warranty and comprehensive technical support.

Use the form below to discuss the best waste-saving solution for you.