CNC cutting oil recycling system saves your business time and money

CNC cutting oil recycling system [Oil saver]

Save money and reduce waste by reusing neat oil from your sliding head machines and lathes. The CNC cutting oil recycling system pumps used oil from a swarf bin back to the machine. You reuse up to 50 percent of your neat oil, making the oil saver tool a great investment.

Contact Wogaard to find out more.

CNC cutting oil recycling system for machining centres

The CNC cutting oil recycling system solves the problem of waste oil in machining industries.

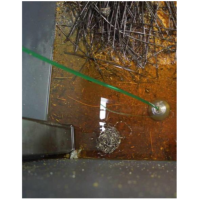

The oil saver tool has a vacuum head that sits in the bottom of a swarf bin. The vacuum pumps used oil back to the machine’s oil reservoir, allowing the oil to be reused. Multiple fitting kits are available, so you can install the oil recycling tool on a range of cutting machines/lathes.

The vacuum receives power from the CNC machine, so no external power source is required. The kit can be installed in 30 to 45 minutes and it’s almost maintenance free.

Install the oil saver on your cutting machines to receive the following benefits:

- Save money: Reduce disposal costs and reuse up to 50 percent of your neat oil. The oil saver kit provides a great return on investment.

- Sell your swarf for more: Your waste swarf stays clean and dry, giving it a higher resale value.

- Save time: Your employees spend less time emptying waste oil from swarf bins and adding oil to the machines.

- Improve working conditions: Reduce oil leaks from chip bins.

- Help the environment: Recycle your oil and reduce waste. The oil saver kit doesn’t require an additional power supply, making it more environmentally friendly.

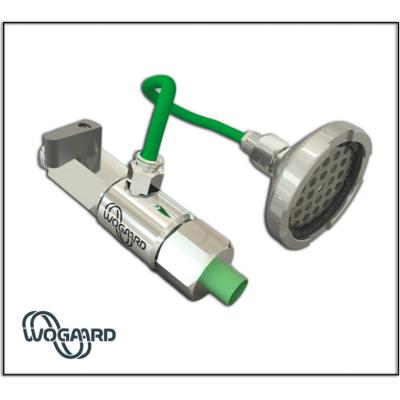

The CNC cutting oil recycling system includes:

- Oil saver unit

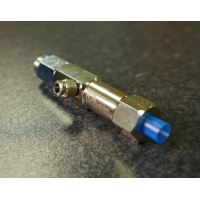

- Vacuum head with non-return valve

- Three-metre, six-millimetre polyurethane hose (can be extended to five metres)

- One-metre, 12-millimetre hose outlet

- T-fitting and straight-fitting kits (for sliding head machines with larger hoses)

- Instruction manual and technical support One-year warranty

Contact Wogaard for full specifications and prices.

Testimonials from users of the neat oil recycling equipment

Wogaard oil recovery systems are installed all over the world. The company has a wide base of happy customers.

Renishaw

“We have reduced the time wasted topping up the oil in the sump of the machines, negated the risk of neat oil leaking onto the shop floor and saved our labourers’ time.”

Technoset

“There is no way we would go back to a shop floor without the coolant and oil savers fitted to our machines…. The swarf bins are clean and dry with material that is ready to be recycled.”

Seco Tools

“The savings are significant and the return on investment is fast.”

Use the form below to request more information about the oil recovery system.